All About Distilled Water

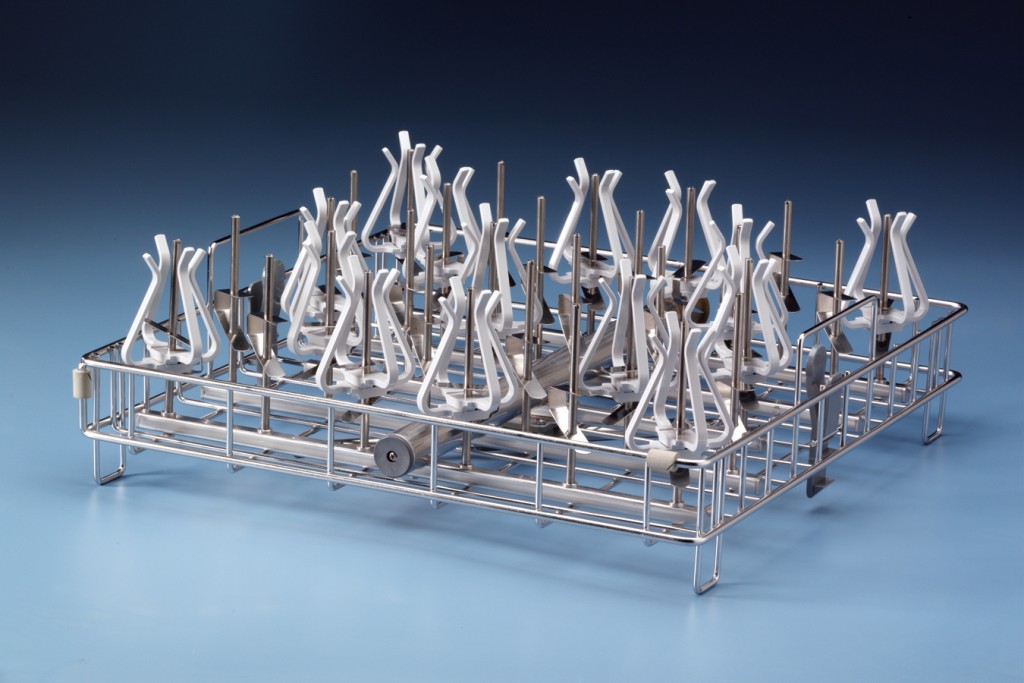

Commercial Distillers

Residential Distillers

Laboratory Distillers

Barnstead and Corning Stills and Parts Can be found here

What impurities will distillers remove?

The distillation process removes almost all impurities from water. Distillers are commonly used for removing nitrate, bacteria, sodium, hardness, dissolved solids, most organic compounds, heavy metals, and radionucleides from water. Distillers remove about 99.5 percent of the impurities from the original water.

What impurities are not removed?

Distillers can allow 0.3 to 0.5 percent of water impurities to exist in the storage container after distilling.

Some volatile organic contaminants (VOCs), certain pesticides and volatile solvents, boil at temperatures very close to water (207-218 degrees Fahrenheit). These types of contaminants will not be substantially reduced in concentration by distillation. Properly equipped distillers can reduce VOC concentrations effectively.

Although bacteria are removed by distillation, they may recolonize on the cooling coils during inactive periods.

Water Testing

Before you buy a water treatment unit, you should know what impurities are in your water supply. To determine the types and amounts of impurities in your water, you should have it analyzed by a certified laboratory. The results of the water test will help determine the best water treatment system to use.

If you obtain water from a private water supply (you supply your own water), you also make the final decision about water testing. However, it is recommended that testing be done on a regular basis. When problems do occur, more frequent testing may be required until a solution is found.

Community water supplies are monitored and treated to protect users from health threatening water impurities. Ask your water supplier for a copy of the latest water test results.

The Distillation Process

Distillers use heat to boil water into steam which is condensed back into water and collected in a purer form. When water boils, it leaves impurities behind in the boiling chamber. The rising steam passes into a cooling section and condenses back into a liquid. The condensed liquid (water) then flows into a storage container.

Distillers remove almost all of the impurities from water supplies. As water is heated the impurities in the boiling chamber increase in concentration. The water left behind in the boiling chamber is discarded and the process is started over.

Distilled water has a bland taste, because the dissolved minerals that give water a pleasing taste have been removed. Distilled water should be stored under sanitary conditions in plastic, glass or stainless steel containers.

Household distillers are designed for providing water for drinking and cooking. It is not economical to distill water for other uses like flushing toilets, bathing, washing clothes, and cleaning.

Types of Distillation Equipment

Distillers are commonly made of stainless steel, aluminum, and plastic materials. These materials do not absorb impurities from water and are easy to clean.

There are two types of distillers: batch units and continuous flow units.

Batch Distillers: Water is poured directly into the boiling chamber. The unit is turned on and the water is heated to boiling. When all the water in the boiling chamber is evaporated, the unit shuts off. Distilled water is removed from the storage container for household use. Batch units can range from 1gallon countertop units to 10 gallon floor units. Batch distillers produce from 3 to 10 gallons of distilled water per day. The smallest distillers are about the same size as a coffee maker.

Continuous flow units

Continuous flow or automatic units are connected to the water supply line. The water level in the boiling chamber is maintained by a float valve connected to the water supply. As distilled water is removed from the storage tank, the unit turns itself on and starts producing more distilled water. A discharge line periodically removes the concentrated impurities from the boiling chamber. Distilled water is either stored in a container or is piped to the use area.

Distiller accessories

Additional storage containers, transfer pumps and special kitchen taps can be installed adjacent to a distiller. Increased storage capacity will only be advantagous for continuous flow units. For example, you can install a kitchen tap and an under-the-sink reserve tank that has a level switch to turn on a small transfer pump. This pump transfers water from the distiller to a storage container located under the sink. When the under-the-sink reserve tank empties it turns on the transfer pump to refill the reserve tank. When the distiller's storage tank empties, it turns itself on and fills the storage containers.

How are volatile organic compounds (VOC) removed?

Distillers can remove VOCs by three methods:

1. gas vents,

2. fractional columns

3. activated carbon filters (ACF).

Distillers that use a combination of VOC removal methods are more efficient than one single method.

Gas vents are small holes drilled into the passage leading to the cooling coils. Gas vents allow VOCs to escape the distiller before they enter the cooling section coils. These holes (one or two) are usually from .045 inches to .065 inches in diameter.

Fractional column distillers use differential cooling to remove VOCs. VOCs are removed when they condense in a different section of the fractional column than where water does. Fractional distillers usually cost more than distillers with gas vents or ACF cartridges.

Activated carbon filters (ACF) trap VOCs. The ACF units are normally located at the end of the cooling coils and remove the VOCs prior to entering the distilled water storage container. ACFs can also be placed in the water supply line to reduce VOCs entering a distiller.

Removal of VOCs in distillers without gas vents, fractional columns or ACFs can also be accomplished with some success by discarding the first pint (1/2 liter) of distilled water in the storage container.

Proper Maintenance

Minerals and other residues accumulate in the boiling chamber as water is boiled away. These minerals and compounds need to be removed occasionally. The boiling chamber of a distiller should be emptied about once a week. When distillation is continuous, the boiling chamber should be emptied more often. If these materials (scale and sediment) are not removed periodically, a distiller becomes inefficient.

Mineral scale buildup from hard water can be difficult to remove without the use of an acid-type cleaner. Commercial cleaning agents are available. The cleaners usually contain sulfamic acid or other organic acids. DO NOT use strong mineral acids like hydrochloric, sulfuric or nitric to clean distillers. Strong acids can damage stainless steel and aluminum. Check the owners manual or consult your local distiller dealer for the appropriate cleaner to use.

To remove the scale buildup from a distiller, fill the distiller with the proper acid mixture to approximately 1/2 inch above the mineral line. Let the acid solution sit for the proper amount of time, then discard and rinse.

An alternative cleaning agent is vinegar because it contains acetic acid, a weak organic acid. Pour a 50 percent solution of vinegar into the distiller to about 1/2 inch above the top of the mineral line. Let the unit sit over night, then discard and rinse. If mineral scale is still present, increase the vinegar concentration or cleaning time.

Other regular maintenance duties may include replacing the ACF cartridge and keeping the gas vent holes free of mineral deposits. These steps are necessary to ensure that distillation units equipped to remove VOCs will effectively perform that function.

Lifespan

The lifespan of any distiller depends on the

levels of impurities in the raw water supply, how often the distiller operates, and how often the distiller is cleaned. A good distiller should last 10 to 15 years with proper maintenance and routine cleaning. The most common repair for distillers is replacing a heating element or a cooling fan.

Cost of Distillation

Equipment Purchase Price

Distillers cost from $200 to $1500 for home use models. Counter top distillers will range from $200 to $500 and automatic models from $600 to $1500. In addition to the purchase cost, there are yearly operation costs. These include electricity, chemical cleaners, and possibly replacement ACFs. Yearly operation costs depend on how often a distiller is used.

Examples of purchase cost:

For about $250, you can purchase a 5 quart batch unit (about the same size as a coffee maker). Five quarts of raw water are poured into the boiling chamber. The unit is plugged in, and the distillation process starts. Distilled water is stored in an external plastic container. The unit shuts off automatically when the boiling chamber is empty. It has a maximum output of 4 gallons per day.

For about $1200, you can purchase a 10-gallon per day continuous flow unit with a 4-gallon storage container. When water is removed from the storage container, the unit refills the boiling chamber and begins distilling. The unit shuts off when the storage container is filled. Typical dimensions of this system are about 3 feet high by 2 feet wide by 1.5 feet deep.

Operation Costs

Distiller operation costs are directly related to the amount of distilled water you will use daily. The largest operation cost is electricity. Small batch distillers range from .25 to .30 gallons per kilowatt-hour (gal/KWH) and larger automatic continuous flow distillers range from .30 to .34 gal/KWH.

The electrical cost is easy to calculate:

Cost = 0.024 x (wattage/production g.p.d.) x Cost of electricity ($/KWH)

For Example:

1100 watt distiller produces 8 gal/day (3hr/gal)

and electricity costs $0.10/KWH

Cost = 0.024 x 1100/8 x 0.10 = $0.33/gal or (33 cents/gal)

Typical electrical cost for a family of four will range from $275 to $400 per year (or $22 to $34 per month), because the average family of four uses 3 gallons/day (1100 gallons/year) of water for drinking and cooking. Consult the owners manual or check with a dealer for the cost of a ACF cartridge replacement for a particular distiller. Cleaning cost increases with increased distiller operation.

Total Cost over the life span of a distiller

The total cost of running a distiller includes the purchase price (or rental cost) and cost of operation (electricity and maintenance cost). Typical operational costs range from $0.35 per gallon to $0.50 per gallon. Bottled distilled water, in comparison, costs from $0.30 to $1.50. Based on the example below, it will cost an average family of four $38.60 per month for distilled water or $456.50 per year.

Example of Total cost of distilled water per gallon:

Lets assume for $800 you could purchase a 1100 watt distiller that would last 10 years at full production of 8 gallons/day and electricity costs $0.10/KWH.

How much will a gallon of distilled water cost?

Cost assumptions:

electricity = $0.10 / KWH

repairs & cleaning = 10% of purchase price/year

10 year life span

1100 watt unit produces 8 gal/day

purchase price = $800

Total cost per gallon over ten years

Purchase price

$800/8(gal/day)/365(days/year)/10years= $0.027/gal

(based on continuous operation)

Electricity

1100wt/1000(wt/KWH) X 3(hr/gal) X $0.10KWH=$0.33 /gal

Repairs & Cleaning

$800 X 0.10/8(gal/day)/365(days/year) (annual cost = 10% of purchase price)= $0.027/gal

TOTAL $0.384/gal or 38.4 cents/gal

A typical distiller might realistically only run 60 to 70 percent of the time. The above total cost per gallon was figured at full production. If the distiller ran 70 percent of the time, the cost per gallon would increase by $0.0314 per gallon. The distiller idle time varies with how much distilled water is needed by the user. Based on the example above, it will cost a typical family $38.60 per month ($456.50 per year) for distilled water.

What are the advantages of distillers?

Distillers remove almost all of the impurities found in water, produce sodium free water, and are relatively easy to maintain. Most distillers are mechanically simple.

What are the disadvantages of distillers?

Distillers have small capacities and use considerable energy to process water. Because of the small capacities, distillers are limited to point-of-use systems. Distillers without gas vents, fractional columns, or ACF units will not remove VOCs. Heat generated by a distiller must be dissipated into the surrounding environment.

Items to consider when purchasing a distiller

Test your water for impurities. A distiller might not be the best treatment alternative.

How much distilled water does your household need? (per day, per year)

What type of distillers will fit into your needs?

How easy is the distiller to clean and/or repair?

What type of convenience level should a distiller offer? (manual or automatic operation)

What will you do with the by-products of distillers -- waste water, waste heat, old ACF cartridges?

Is it designed to remove VOCs? Some distillers are designed to remove VOCs but many are not.

What is the cost of maintenance?

Purchase price does not directly indicate a distiller's performance. A moderately priced unit might work as well as expensive units.

Don't buy more equipment than you need.

Equipment should carry UL and NSF or AWQA approval.

Distillers can be purchased here Barnstead Stills and Parts Can be found here

--------------------------------------------------------------------------------

For Further Information

For further information contact your local county extension office or state health department.

References:

FS-5Drinking Water: Treatment Guidelines. University of Maryland Extension

9.729Drinking Water Treatment Devices: Distillers. Colorado State University Extension

HE-430HouseHold Water Treatment. North Dakota State University Extension

MWPS-14 Private Water Systems. Midwest Plan Service

Water Treatment Handbook. Rodale Testing

Funding for this publication was by the U.S. Department of Agriculture, Extension Service, under project number 90-EWQI-19252.

AE-1032, April 1992

http://www.ag.ndsu.edu/pubs/h2oqual/watsys/ae1032w.htm

|

Images are representative of the products. Images may or may not be of the actual product. If it is important e-mail us for an actual image if available.

* Flat Rate UPS shipping when able to ship via UPS and is in the USA excluding Hawaii and Alaska.

Larger Items may not be able to ship via UPS, in that case freight charges will be quoted seperately.

International shipping will be quoted after the order is placed. You will have the opportunity to cancel before we finalize your order.

Terms and conditions

Credit Application

Privacy

Policy

List All Products

|